Types of Concrete

There are many different types of concrete used depending on the application. It's important to know the difference so that your project can stand the test of time all while looking great. We use various mixes for driveways, patios, porches, walkways, and more. Below are three different packages we offer for concrete:

- 40 drive, 4000 PSI, 6 bag mix

- Dura Water Reducer, Premium 6 bag mix

- 45 drive, 4500 PSI, Premium 6 1/2 bag mix

Why be subject to one choice with your concrete contractor? Here at Arpino, we like to educate you on which choice fits your needs, budget, and design choices. These 3 types of concrete are the best 3 options. Our competitors tend to use the standard mix available.

Concrete Sealer

All concrete in a 4 season state should consider being protected with a water based sealer that we offer as well. The purpose of the sealer is to protect the concrete from surface damage, corrosion, and pealing and scaling. The sealer blocks the pores in the concrete to reduce the absorption of water and salts to form an impermeable later which prevents such materials from even entering the concrete.

Dow Corning Concrete Caulk Sealant

The elite in caulking, this contractor-grade sealant is not available to homeowners at home improvement stores. It is the top of the line sealant typically used around windows and pool areas, we use this for three reasons:

- Protect water from getting under driveway to prevent heaving in the winter

- No weeds can grow in the cracks during the summer

- Provides a great finished look

Fiber Mesh & Wire Mesh

Fiber mesh is a great addition to a concrete mix as it serves a few purposes: it strengthens concrete during the vital curing process, and also helps prevent cracks from spreading near footings that heave up and down during the winter.

Wire mesh is a welded wire grid made up of low carbon steel or stainless steel wire. It's available in various sizes and shapes. It helps prevent movement of the concrete.

The difference between the two is the cost during installation. The Fiber Mesh is added directly to the concrete, so there aren't any costs associated with handling it, placing it on the ground, or providing structural support. Wire mesh, on the other hand, needs to be laid out on the ground, tied together, supported in the air before the concrete gets poured, and is harder to work with. It provides a much stronger concrete product, but is also 3 times more expensive than the Fiber Mesh.

Get in touch with us and we can provide you with a free estimate on adding either fiber or wire mesh to your driveway or other concrete project.

Sub-Grade prepartion & Stone Base

There are two basic types of stone that we use in all of our projects: 3/4 Down Stone, and 21AA Stone base. Most contractors in the area just use the 21AA, but we like to offer the 3/4 Down stone upgrade for better, long-lasting installations that require less maintenance. Other times, we like to recommend the 3/4 Down based on the sub-grade of your area due to the differences in soil types. You can read more about how this affects your concrete project in our City Reference guide.

A properly prepared sub-grade must be uniform in both the soil and the compaction before even starting to lay down the base material. By having the proper soil and compaction, it will provide adequate support and ensure an even slab thickness once the concrete is poured. That is why it is imperative that your concrete contractor is knowledgeable in the area, and knows how to properly prepare the sub-grade. We always remove any soft spots and use anywhere from 2 to 4 inches of crushed rock as part of your sub-grade, depending on the degree of expansiveness.

Geo Grid Stabilization

A great upgrade that we always recommend is utilization what is called a Geo Grid, which is designed to provide a quick, long term solution to stabilizing and strengthening roads, parking lots, and driveways. The Geo Grid confines stones and soil particles from moving, and prevents any lateral shearing. They are great because it reduces the pressure applied to the sub-grade, meaning less settling and heaving over time as the ground expands and contracts from our 4 seasons here in Southeastern Michigan.

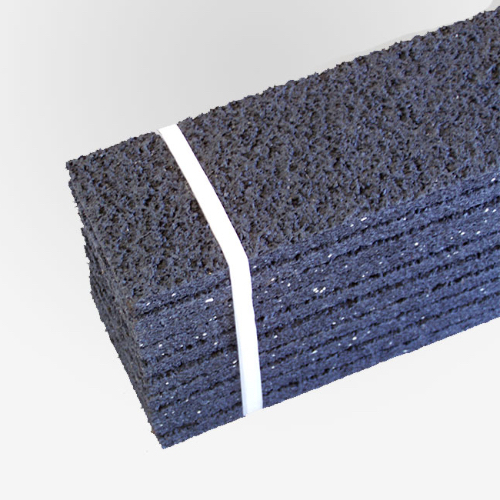

Rubber Reflex Expansion Joint

An example of a quality-first product, we chose this expansion joint product over other inferior products that our competitors typically go with because it is environmentally friendly, top of the line in quality, and made right here in the USA. It does run slightly more expensive, but will last the lifetime of the job and we couldn't recommend it more. Here are some facts about why we use this in every concrete job we do:

- The USDA testing found that Reflex is far less susceptible to termite penetration than other expansion joints

- In the typical home project, about 6 passenger tire cars worth are recycled, keeping them out of landfills

- Made from environmentally friendly materials in the USA